Valogix has developed the next-generation of cutting-edge inventory planning and optimization technology. After years of addressing complex customer’s inventory planning issues VALOGIX DMRP Inventory Planner will transform the way you plan and manage your inventory.

Valogix inventory planning solutions are proprietary multi-stage planning engines. This means the entire process from forecasting, to inventory rationalization and optimization, to planning and replenishment is managed within one solution. This provides several advantages over competitive solutions where multiple modules are required to manage this process. These advantages are:

Forecasting and Planning – every item at every location

-

Stock Level Setting – considers forecast, lead time, order frequency,

-

Desired service level and variability in demand

-

Replenishment – Purchase Orders, Production Orders, Stock Transfers

-

Optimization – reduces inventory investment and increases service

The advantages of multi-stage planning are:

-

Speed an efficiency

-

High degree of accuracy and reliability

-

Less costly to buy and maintain

-

Manages wild cards like demand variability automatically

Material Requirements Planning (MRP)

The purpose of Material Requirements Planning (MRP) is to determine how much of each product or component is needed. MRP also decides when the product is required. Every item can have either Independent Demand or Dependent Demand.

-

Determine when to order stock to support the production schedules.

-

Traditional MRP works well with dependent demands from factory orders. It uses a time-phased planning to manage the back-scheduling and creates an even-flow of goods.

-

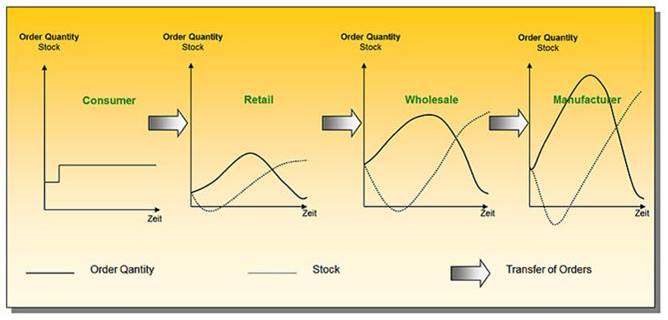

A major objective is the reduction of lead time for demand signals to traverse the internal supply chain.

-

A second objective is to predict the major “bullwhips”. This occurs when several locations submit orders to the same supplying warehouse very close together.

-

There is a Parent\Child relationship that is inherent in the planning process. Additionally, Substitutes and Supersedes further complicate a difficult process.

VALOGIX DMRP Inventory Planner Benefits

Valogix automates the entire inventory planning processVALOGIX inventory planning solutions can plan an unlimited number of items and locations. There is no limit to what you can achieve to improve your positive cash flow.

Valogix creates a forecast, sets optimal stocking levels and identifies your ideal inventory investment. It compares the recommended stock to your actual stock. Valogix makes it easy to see and take action on obsolete, excess and inactive items. You can quickly filter, sort and drill down into item detail and make better decisions.

With thousands of items to plan, Valogix can handle the planning faster and easier, leaving you time to work with your customers.